Engineering Silver Surfer (Scratch built L1 Certification Rocket)

Publish date: Jan 7, 2026 | Tags: rocketryFlight Plan

Mission and Design

Intro

Although I built an L1 rocket before with my L1 class @ Comet Rocketry (Sponge Bob) - it has yet to launch due to scheduling issues with the team. Once the semester was done I decided I wanted to do an L1 just by myself, and launch during the Spring ‘26 semester.

While my work with the AIAA competition team focuses on complex L3 high-power rockets, building an L1 scratch rocket offers valuable “full-stack” experience; From simulation (OpenRocket, RasAERO, RocketPy) to manufacturing and avionics.

Acknowledgement: This build leverages resources from the Comet Rocketry UTD club, Dr. Kurt Satter, and Mark Canepa’s “Modern High Power Rocketry 2”.

Design Philosophy

Airframe

Selected the 3" diameter body to make use of some old Scotch packing tubes I had lying around. At 0.1" difference, it felt like a good alternative. The length of the rocket was selected to be made out of a single tube, with room for making mistakes in 1 body tube and be able to recover without needing additional tubes.

Nosecone

The nosecone type selected was an Ellipsoid nosecone, given its low drag coefficient below Mach 0.8, as Silver Surfer is only supposed to reach Mach 0.5 (550 ft/s). The material for the nosecone is LW PLA (AKA Aero PLA), due to 50% weight reduction compared to regular PLA. To increase impact resistance, 5 walls were set when printing, and 25% infill.

The other types and their pros/cons can be found below for reference

| Shape | Geometry | Best for | Notes |

|---|---|---|---|

| Conical | A simple straight-sided cone. Very easy to draw, very high drag at subsonic speeds. | Scale models / Mach 2+ rockets | Not aerodynamic enough for Silver Surfer’s Mach 0.5. |

| Ogive | The “classic” rocket shape. The curve is a segment of a circle where the base is tangent to the body tube. | Most hobby rockets | Easy to manufacture, reduce space for avionics bay. |

| Parabolic | Shape defined by a parabola and similar properties as Ogive. | Sub/Transonic rockets | Same as Ogive. |

| Haack | Optimized for minimum drag at specific Mach numbers. | High altitude rockets (L2/L3) | Overkill for an L1 given the ~2000 ft max height Silver Surfer’s supposed to reach |

Avionics

The avionics for Silver Surfer is just a simple PCB with a BMP-280 pressure sensor, an SD-Card to collect the pressure data, and a RP2040 zero as the brains. The Circuit was built using Altium Designer and manufactured using the CNC. The nosecone has 2 little channels added to its design, and the payload bay has the negative for those two channels to facilitate alignment of the screws that holds the payload bay attached to the nosecone during the flight.

Motors

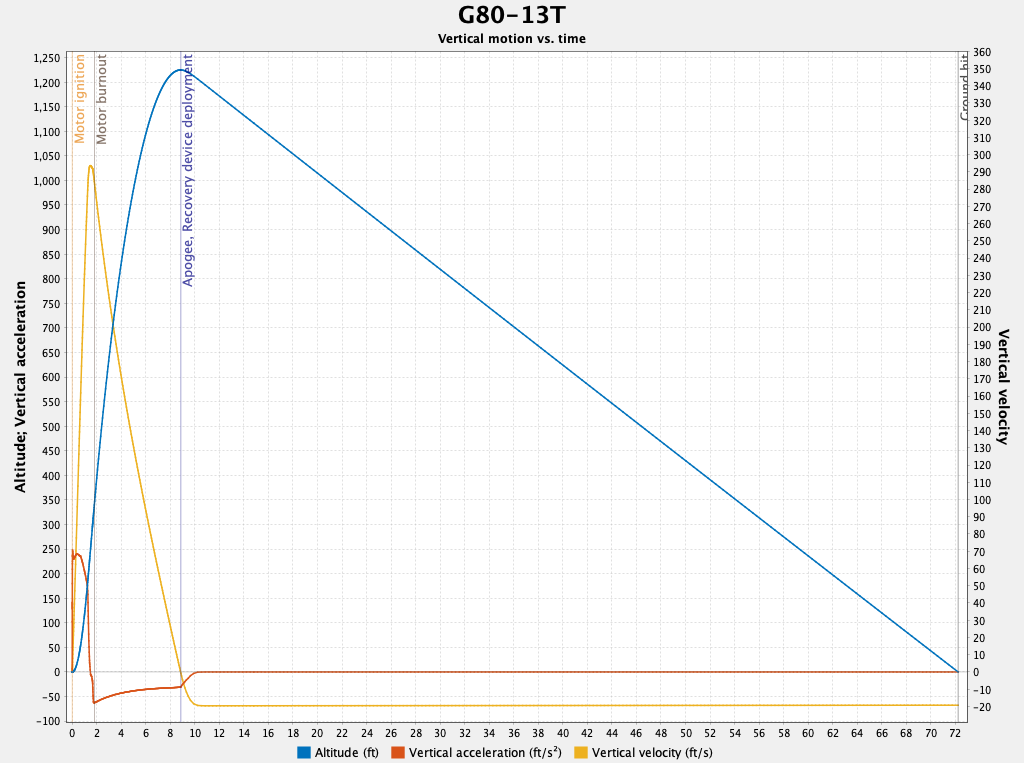

For the actual certification launch, I’ve opted to go with a disposable AeroTech H195NT-14A, modified down to a 10-second delay, as per the OpenRocket simulations optimal delay time of 9.89s. Mark Canepa's High Power Rocketry book recommends the maiden flight to be done with a G motor to verify everything works correctly and the rocket is recoverable, and based on my local HobbyTown stock, I selected the Aerotech G80-13T, with its delay time reduced to 7 seconds.

Recovery

For recovery, I’m going with an Estes 36" Ripstop Parachute if the wind is mild or an Aerotech 30" fabric parachute if the wind is heavy. With the 36" parachute the ground speed should come at around 17ft/s, on the slow-but-safer-side, while the 30" one comes at around 22ft/s. Mark Canepa’s suggestion is to stay below 25ft/s.

To attach the parachute I selected a 1/4" Tubular Kevlar shock-cord (15’ long), and a Banwear flame resistant blanket to protect the avionics bay from the ejection gases. My first option was recovery wadding, but for reusability purposes I chose the blanket.

To attach the parachute I selected a 1/4" Tubular Kevlar shock-cord (15’ long), and a Banwear flame resistant blanket to protect the avionics bay from the ejection gases. My first option was recovery wadding, but for reusability purposes I chose the blanket.

The shock-cord is attached to the bulkhead with a 1/4" U-bolt (According to LOC Precision its rated up to 60lb, way above Silver Surfer’s ~2.5lb weight, including motor) and to the forward centering ring with a 1/8" closed eyebolt, using 1/8" quick-connects for reusability

The shock-cord is attached to the bulkhead with a 1/4" U-bolt (According to LOC Precision its rated up to 60lb, way above Silver Surfer’s ~2.5lb weight, including motor) and to the forward centering ring with a 1/8" closed eyebolt, using 1/8" quick-connects for reusability

Fin set

For the finset, I went with a 4 fin Trapezoidal set. The decision was made to achieve better stability at the expense of additional drag - Silver surfer is relatively short at slightly over 2’. As a bonus, I’m hoping that in the event of a fast landing, the additional fin saves the body from further damage. The trapezoidal shape was selected for durability (given the root chord) and ease of manufacturing with a laser cutter.

To cut the lower body tube’s fin slots, I designed a pressure sleeve in Fusion 360, with multiple markings for 3 and 4 fins with a 1/8" thickness (120 degree, and 90 degree separation respectively). Additionally, I added a center point between the 4 fins to mark the exact spot for the rail buttons.

Components

A mix of materials was selected for the centering rings, bulkhead, couplers, and inner tube.

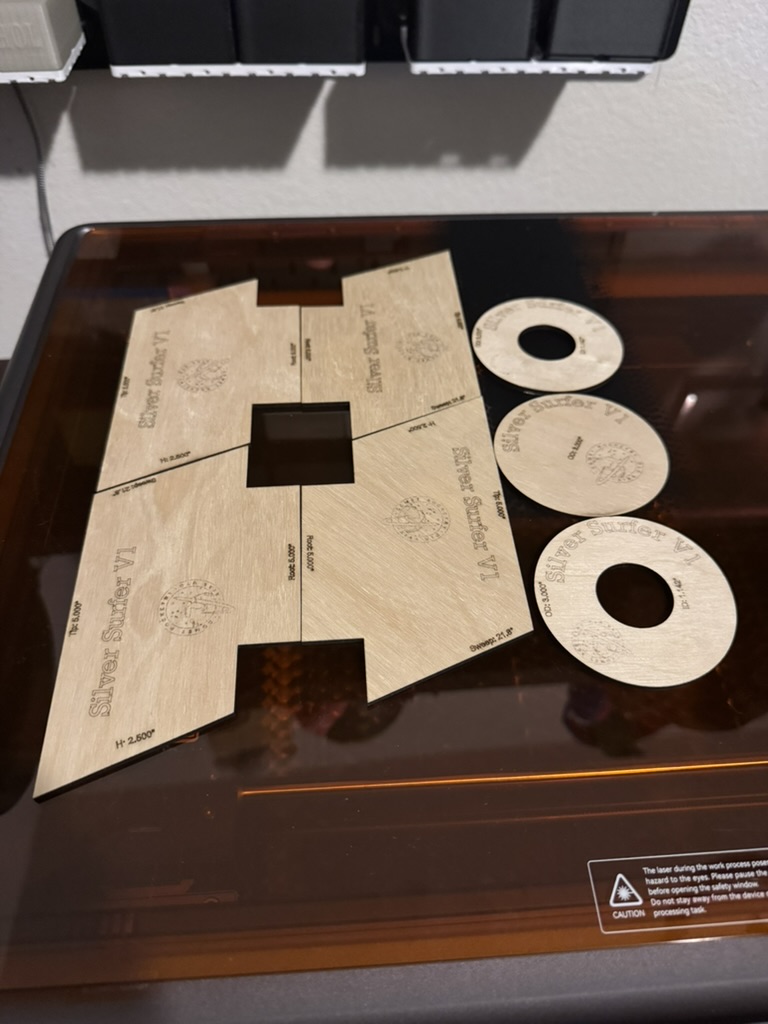

Centering Rings and Bulkhead

I chose 1/8" Birch Plywood for the rings to utilize my existing stock of laser-cuttable wood, and reduce fabrication time (< 15 minutes for a full set of 4 fins, 2 centering rings, and a bulkhead). I built a fabrication tool on the open source OpenRocket python parser we open sourced with AIAA UTD Comet Rocketry to export SVGs for bulkheads and centering rings, including the addition of eyebolts and U-bolt holes. This enables me to make mistakes freely, given that the pieces are quickly fabricated.

Couplers and Inner tube

I went with standard cardboard couplers and inner tube (motor mount) for convenience - I had cardboard tubes laying around, luckily of the correct diameters.

Launch lugs

Lastly, for the launch system, I went with 1/2" Delrin rail buttons purchased from LOC Precision (https://rail-buttons.com/ wasn’t available). Additionally, I’ve designed my own rail buttons in Fusion 360 and I’m in the process of learning how to use the 4th Axis tool in my CNC to produce my own rail buttons for future launches, also made out of Delrin (1/2" - 1ft)

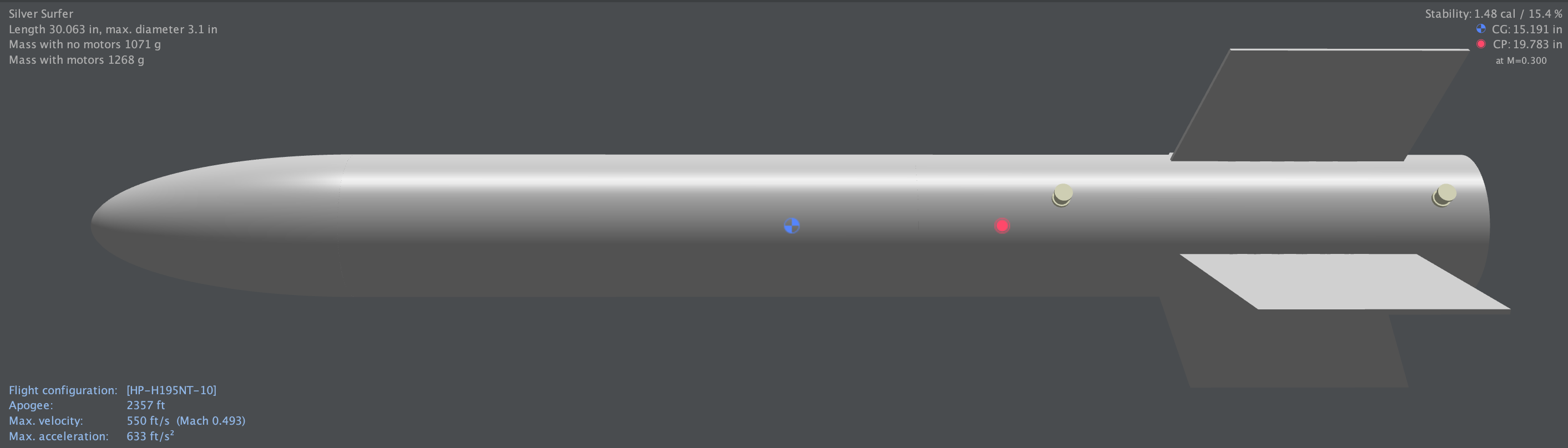

OpenRocket

Design Info

| Silver Surfer | |

|---|---|

| Stages | 1 |

| Mass (w/o motor) | 1071g |

| Diameter | 3.1 |

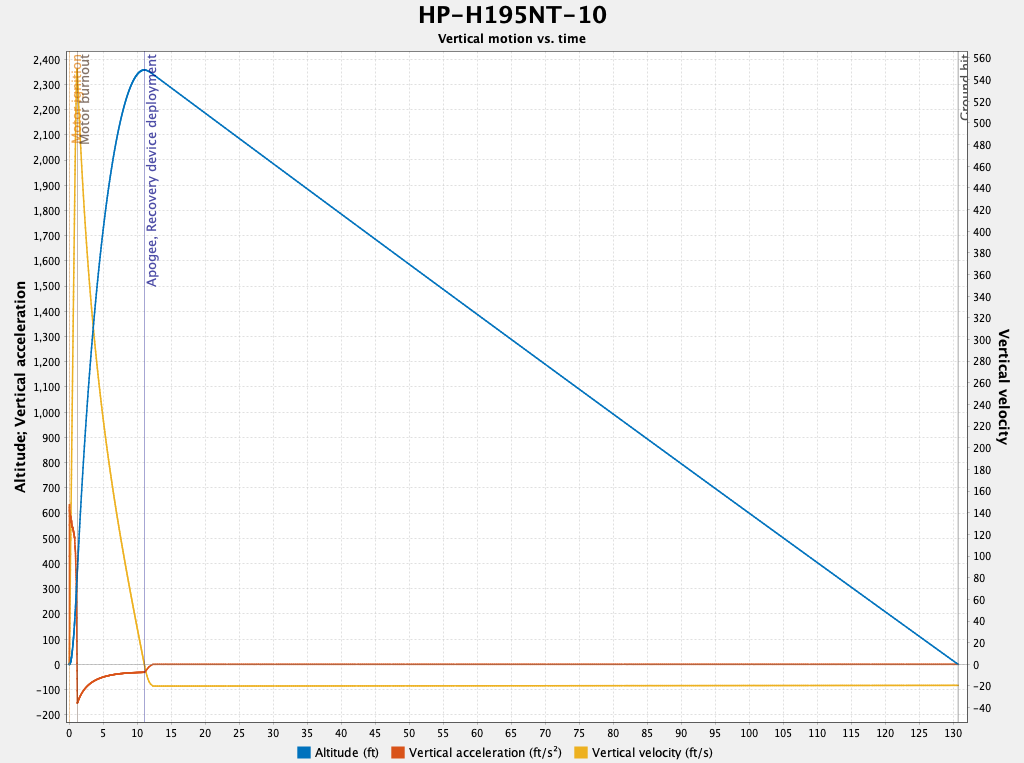

H-195 Motor Stats

| HP-H195NT-10 | Aerotech |

|---|---|

| Mass (w/ motor) | 1268g |

| Stability | 1.48cal |

| Center of Gravity | 15.91in |

| Center of Pressure | 19.783in |

| Altitude | 2457ft |

| Flight Time | 131s |

| Time to Apogee | 11s |

| Optimum Delay | 9.87s |

| Velocity off Pad | 64.9ft |

| Max Velocity | 550ft/s |

| Velocity at Deployment | 6.81ft/s |

| Landing Velocity | 20.2ft/s |

| Thrust (avg/max) | 205N/257N |

| Burn Time | 1.16s |

| TWR | 16.47:1 |

| Weight | 115g |

| Size | 1.14/7.99in |

G-80 Motor Stats

| G80T-13 | Aerotech |

|---|---|

| Mass (w/ motor) | 1199g |

| Stability | 1.62cal |

| Center of Gravity | 14.749in |

| Center of Pressure | 19.783in |

| Altitude | 1225ft |

| Flight Time | 72.2s |

| Time to Apogee | 8.87s |

| Optimum Delay | 7.06s |

| Velocity off Pad | 39.4ft |

| Max Velocity | 294ft/s |

| Velocity at Deployment | 13.7ft/s |

| Landing Velocity | 20.6ft/s |

| Thrust (avg/max) | 78N/102N |

| Burn Time | 1.71s |

| TWR | 6.63:1 |

| Weight | 62.5g |

| Size | 1.14/4.88in |